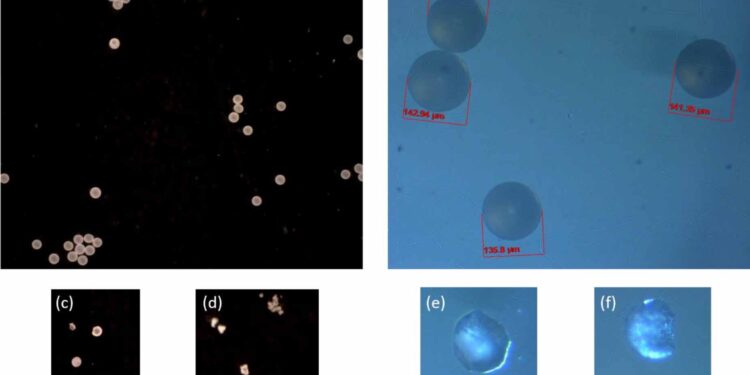

Images of polyethylene microspheres obtained by digital microscopy (a), (c), (d) and by optical microscopy (b), (e), (f). Microplastics are shown (a), (b) without; and (c)–(f) with 30–96 h of UV exposure in the presence of TiO2 photocatalyst. Credit: Nanotechnology (2024). DOI: 10.1088/1361-6528/ad5dc5

In a world first, researchers at the University of Waterloo have used 3D imaging technology to understand the finest details of microplastics, paving the way for more efficient methods of recycling plastic waste.

Micro- and nanoplastics, tiny plastic particles that are formed when larger plastics break down, are causing an exponentially worsening environmental crisis. Because they are difficult to break down safely, plastic pollution poses a significant threat to ecosystems, wildlife, and human health.

Scientists are struggling to understand the exact process of degradation of these micro- and nanoplastics, especially at the micro- and nanoscale, which is hampering efforts to mitigate their environmental impact. Observing and understanding the workings of microplastics in their smallest details and how they decompose is essential to eradicating them from our environment.

In collaboration with the National Research Council (NRC), the researchers leveraged 3D imaging technology in addition to traditional 2D microscopy, allowing them to observe the degradation of micro- and nanoplastics in unprecedented detail.

The study, “3D Imaging of Photocatalytically Degraded Micro- and Nanoplastics,” was recently published in Nanotechnology.

“Most images taken under a microscope provide a two-dimensional view, similar to a medical X-ray, which gives us some information but lacks depth,” said William Anderson, a professor in Waterloo’s department of chemical engineering.

“However, 3D imaging is comparable to a CT scan, providing much more detailed information about the structure and degradation of microplastics. This level of detail has been incredibly difficult to achieve, but it is essential to understand what is happening on the surface of micro- and nanoplastics and how the degradation processes work.”

To obtain this new visual data, the research group used a novel combination of physical and biological approaches. They used a photocatalytic process that treated micro- and nanoplastics with UV light and a titanium oxide catalyst. The team was thus able to observe and analyze the degradation at the microscopic scale.

“This methodology reveals not only that degradation occurs, but also how and where exactly it occurs on the surface of micro- and nanoplastics,” said Boxin Zhao, professor of chemical engineering and chair of nanotechnology at the University of Waterloo. “This knowledge is crucial for developing more efficient methods of breaking down plastics at the micro- and nanoscale.”

Anderson and Zhao, in collaboration with researchers from the University of Waterloo’s Department of Chemical Engineering and Department of Biology, are developing biocycling methods in which microplastics could be used as a carbon source for bacteria. The bacteria would ingest the microplastics and then excrete an environmentally friendly biopolymer that could be used to create new materials such as plastic bags or packaging films.

This study has broader implications for the Waterloo research team, which is currently developing a multidisciplinary research initiative on plastics biocycling.

This collaboration highlights the importance of bringing together different areas of expertise to address complex environmental challenges. This research provides valuable insights that could pave the way for more efficient methods of recycling plastic waste and contribute to a circular economy.

More information:

Aleksander Cholewinski et al, 3D imaging of photocatalytically degraded micro- and nanoplastics, Nanotechnology (2024). DOI: 10.1088/1361-6528/ad5dc5

Provided by the University of Waterloo

Quote:3D imaging allows researchers to observe degradation of micro- and nanoplastics in unprecedented detail (2024, September 5) retrieved September 5, 2024 from

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.